Life Time of Unlimited Service or Replacement with best-in-class period material.

Our Premium Zirconia crown now incorporates CAD/CAM precision, allowing for layered, full-contoured, multi-layered, polished and glazed options, resulting in a natural look.

ADAMAS 100® crowns are not just about manufacturing a prosthesis, it is an art which mimics every aspect of the natural tooth using craftsmanship, dexterity, finesse and the talents of technicians and dentists. It is an impeccable piece of art.

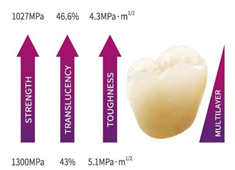

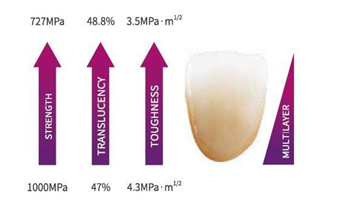

ADAMAS 100® offers a combination of enhanced translucency and flexural strength, providing an ideal aesthetic solution for anterior or posterior crowns, multi-unit bridges, as well as inlays and onlays.

ADAMAS 100® is more translucent than monolithic zirconia and has the translucency of lithium disilicate without sacrificing the flexural strength of Zirconia.

Our manufacturing process involves the milling of Adamas 100® from a gradient block of Zirconia, renowned for its superior base color, meticulously selected to enhance the aesthetics of dental restorations. With a comprehensive range of 20 shades available, including four bleach shades, our clientele has the flexibility to select the most suitable option for their specific requirements.

Utilizing cutting-edge software within the realm of digital dentistry, such as intra-oral scanners, proficient dental technicians are empowered to consistently craft aesthetically driven prosthesis that significantly enhance the quality of one's smile over an extended period.

The adoption of 3D intra-oral scanning technology facilitates the acquisition of precise dental recordings, thereby circumventing the reliance on conventional impression-taking techniques involving rubber base or alginate materials. This transition to digital methodologies not only ensures heightened accuracy but also minimizes patient discomfort during the impression process.

Through the integration of advanced software and hardware components, we can deliver restorative solutions that exhibit superior aesthetics and longevity, thereby fostering enduring patient satisfaction and oral health outcomes.

CAD/CAM milled PMMA interim crowns are strategically employed to mitigate the potential impact of anatomical changes within the patient's oral cavity during the fabrication phase. This Pre-emptive measure ensures the precise fit and functionality of the final restoration by providing temporary crowns that closely mimic the intended form and function.

| Aesthetics | |

|---|---|

| Strength | |

| In-lab time | < 5 Working days |

| Process | Designed and milled using CAD/CAM |

| Occlusal Clearance | 1.0mm -2.0 mm |

| WARRANTY | An everlasting warranty |